OEM/ODM Cheap Thermal Transfer Film Wholesaler in China

In the realm of design and manufacturing, innovation is key to staying ahead of the curve. Whether in fashion, automotive, electronics, or home decor, finding creative and efficient ways to enhance designs is essential for success. Thermal transfer film, often overlooked but incredibly versatile, has emerged as a powerful tool for designers and manufacturers alike. With its ability to add texture, color, and pattern to a wide range of surfaces, thermal transfer film is revolutionizing the way products are designed, manufactured, and experienced.

Understanding Thermal Transfer Film:

Thermal transfer film, also known as heat transfer film or foil, is a thin layer of material that is applied to a surface using heat and pressure. The process involves transferring the film onto the substrate, such as fabric, plastic, metal, or paper, to create a decorative or functional finish. The film can be customized with various colors, patterns, textures, and finishes, making it a versatile and adaptable solution for a wide range of design applications.

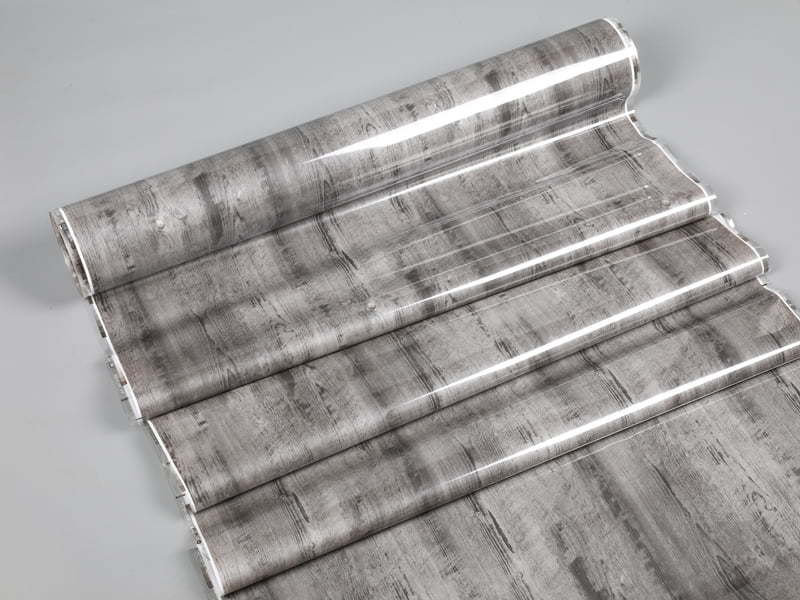

Adding Texture and Dimension:

One of the key benefits of thermal transfer film is its ability to add texture and dimension to surfaces. Unlike traditional printing methods, which are limited to flat or two-dimensional designs, thermal transfer film can create three-dimensional effects that enhance the look and feel of a product. By using embossed or textured films, designers can add depth, detail, and tactile appeal to surfaces, creating visually stunning and engaging designs that captivate the senses.

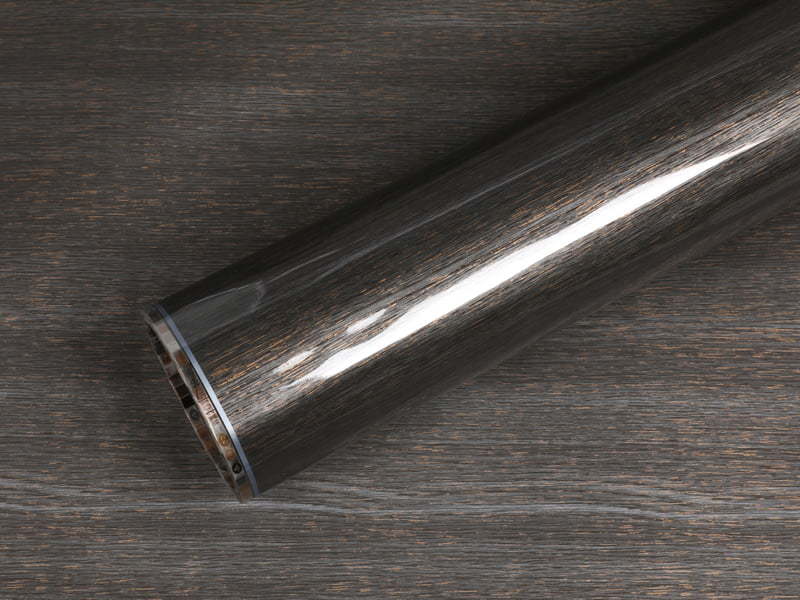

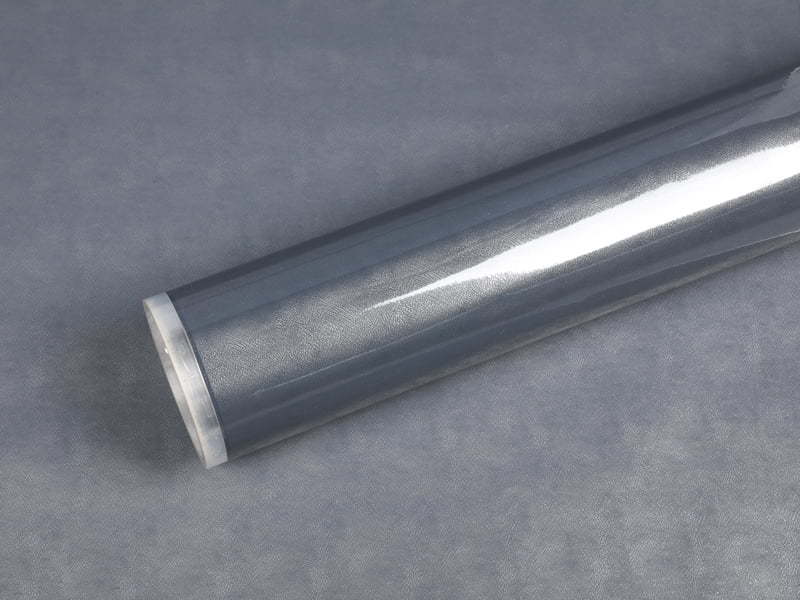

Incorporating Color and Pattern:

Thermal transfer film offers endless possibilities for incorporating color and pattern into designs. Whether you're looking to create bold, vibrant graphics or subtle, understated motifs, the film can be customized to match your vision. With a wide range of colors, finishes, and effects available, including metallics, holographics, and fluorescents, designers can achieve virtually any look or style imaginable. From fashion apparel and accessories to consumer electronics and automotive interiors, thermal transfer film allows for limitless creativity and customization.

Enhancing Durability and Performance:

In addition to its aesthetic benefits, thermal transfer film also offers practical advantages in terms of durability and performance. The film forms a strong bond with the substrate, creating a permanent and long-lasting finish that is resistant to fading, scratching, and peeling. This makes it ideal for applications where durability and longevity are important, such as outdoor signage, industrial labels, and automotive trim. Additionally, thermal transfer film can be engineered with special properties, such as UV resistance, chemical resistance, or antimicrobial protection, to meet specific performance requirements.

Streamlining Production Processes:

Another advantage of thermal transfer film is its ability to streamline production processes and reduce manufacturing costs. Unlike traditional decorating methods, such as screen printing or embroidery, which require multiple steps and specialized equipment, thermal transfer film can be applied quickly and easily using heat and pressure. This simplifies the production process, reduces labor and material costs, and increases production efficiency. Additionally, thermal transfer film can be applied to a wide range of substrates, including curved or irregular surfaces, allowing for greater design flexibility and versatility.

Supporting Sustainability Initiatives:

As sustainability becomes increasingly important in the design and manufacturing industries, thermal transfer film offers eco-friendly solutions that support environmental initiatives. Unlike traditional decorating methods, which may involve harsh chemicals or excessive waste, thermal transfer film produces minimal waste and emissions during application. Additionally, the film can be engineered with eco-friendly materials, such as recyclable plastics or water-based adhesives, to minimize environmental impact. By choosing thermal transfer film, designers and manufacturers can reduce their carbon footprint and support sustainable practices.

Inspiring Innovation and Creativity:

Thermal transfer film is inspiring innovation and creativity across a wide range of industries. From fashion and apparel to automotive and electronics, designers are pushing the boundaries of what's possible with this versatile material. By embracing thermal transfer film, designers can create unique and memorable designs that stand out in a crowded marketplace, differentiate their products from competitors, and enhance the overall consumer experience.

English

English

русский

русский

Español

Español

عربى

عربى

Türk

Türk