White Hot Stamping Foil Price For Sale Company Maker Manufacturing

White hot stamping foil is a versatile and sophisticated tool in the world of printing and packaging. Its ability to add a touch of elegance and luxury to various materials makes it a sought-after choice for designers and manufacturers alike. However, achieving flawless results with white hot stamping foil requires skill, precision, and attention to detail. Whether you're a seasoned professional or a novice looking to master the technique, here are some tips to help you achieve impeccable results every time.

Choose High-Quality Foil: The quality of the foil you choose can significantly impact the final result of your hot stamping project. Opt for high-quality white hot stamping foil from reputable suppliers to ensure consistent performance and flawless results.

Prepare Your Surface: Before applying white hot stamping foil, make sure the surface is clean, smooth, and free of any dust or debris. Use a mild cleaning solution and a lint-free cloth to remove any dirt or residue that may affect adhesion.

Adjust Temperature Settings: The temperature of your hot stamping machine plays a crucial role in achieving results. Consult the manufacturer's instructions for recommended temperature settings and adjust them accordingly based on the type of material you're stamping.

Test for Adhesion: Before stamping your final product, conduct a test run on a small, inconspicuous area to ensure proper adhesion and alignment of the foil. This will allow you to make any necessary adjustments before proceeding with the full run.

Use Proper Pressure: Achieving the right amount of pressure is essential for ensuring crisp, clear stamping results. Too much pressure can cause the foil to smudge or wrinkle, while too little pressure may result in incomplete or uneven transfer. Adjust the pressure settings on your hot stamping machine as needed to achieve results.

Ensure Even Heating: Uneven heating can lead to inconsistent results and poor adhesion of the foil. Make sure that the heat is evenly distributed across the stamping die to ensure uniform transfer of the foil onto the substrate.

Allow Sufficient Dwell Time: Dwell time refers to the amount of time the foil remains in contact with the substrate during the stamping process. Allow sufficient dwell time to ensure proper adhesion and transfer of the foil onto the surface.

Use the Right Technique: The technique you use during the stamping process can have a significant impact on the final result. Whether you're using a flatbed, cylinder, or rotary stamping machine, make sure to follow proper stamping techniques to achieve flawless results.

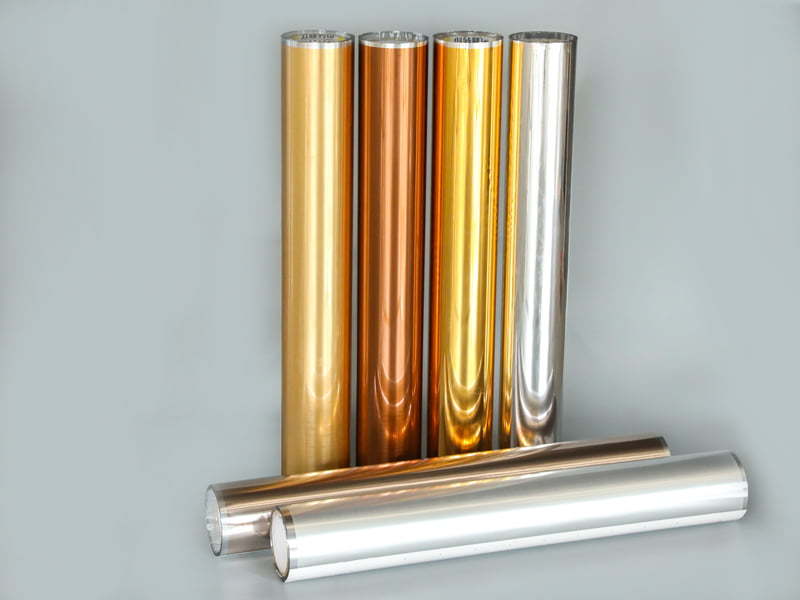

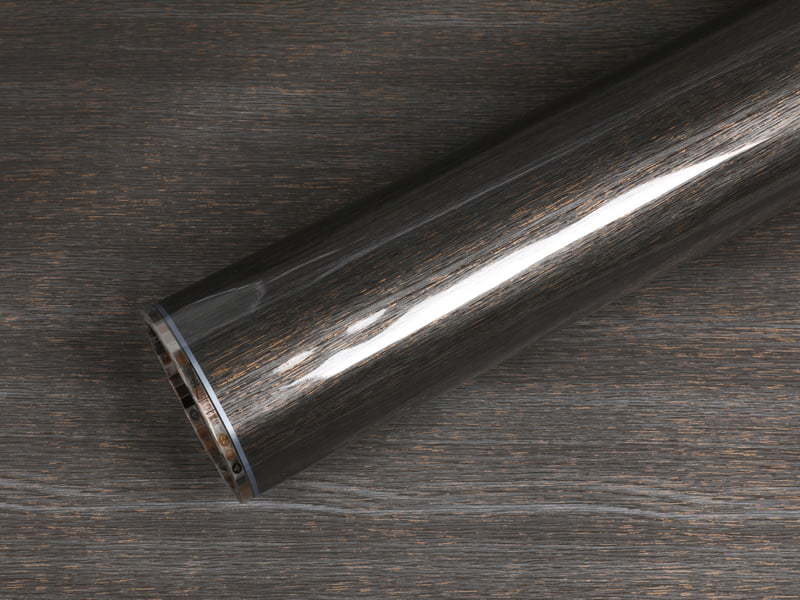

Experiment with Different Foil Types: White hot stamping foil comes in a variety of formulations, each offering unique properties and effects. Experiment with different types of foil to achieve the desired look and feel for your project, whether it's matte, glossy, metallic, or holographic.

Practice Proper Alignment: Proper alignment is essential for achieving professional-looking results with white hot stamping foil. Use guides, registration marks, or alignment tools to ensure accurate placement of the foil on the substrate.

Handle Foil with Care: White hot stamping foil is delicate and prone to damage if mishandled. Handle the foil with care to avoid creasing, tearing, or wrinkling, which can affect the quality of the stamping results.

Consider Substrate Compatibility: Not all substrates are suitable for hot stamping with white foil. Before starting your project, consider the compatibility of the substrate with the foil to ensure adhesion and transfer.

Maintain Clean Equipment: Regular maintenance and cleaning of your hot stamping equipment are essential for achieving consistent results. Keep the stamping dies, platens, and other components clean and free of debris to prevent issues such as uneven stamping or poor adhesion.

English

English

русский

русский

Español

Español

عربى

عربى

Türk

Türk