In the realm of modern printing and decorative applications, PET heat transfer film has emerged as a technological marvel, revolutionizing the way we add vibrant designs to various surfaces. This ingenious design incorporates cutting-edge technology to transfer intricate patterns and colors onto substrates using heat.

Understanding PET Heat Transfer Film:

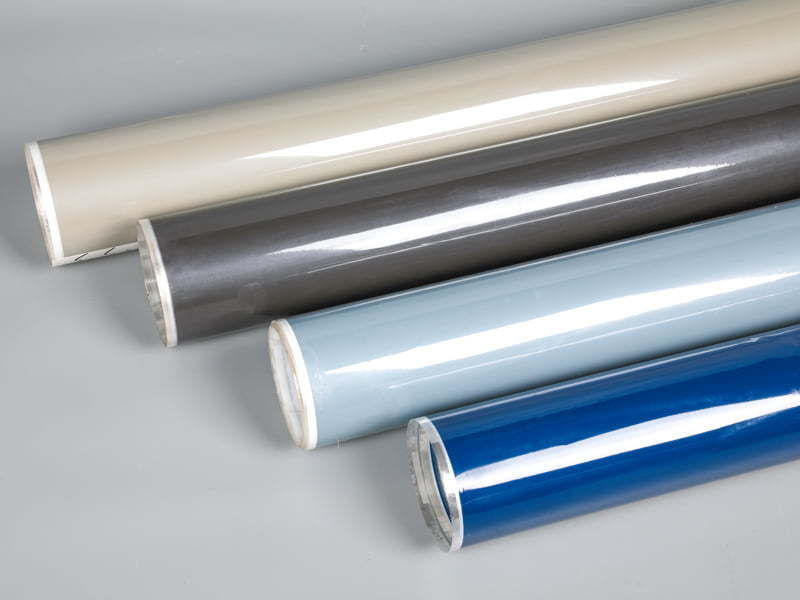

Polyethylene terephthalate, commonly known as PET, serves as the foundation for this innovative heat transfer film. PET is a thermoplastic polymer known for its clarity, strength, and versatility. The design of PET heat transfer film involves a meticulous process that transforms this flexible and transparent material into a carrier for vibrant and detailed designs.

The Layered Structure:

At its core, PET heat transfer film boasts a layered structure that plays a pivotal role in its functionality. The film typically consists of several layers, each serving a specific purpose in the heat transfer process:

Base Layer (PET Film): The bottom layer is the PET film itself, providing the foundation for the entire structure. This layer's transparency ensures that the colors and details of the design remain true when transferred to the final substrate.

Release Layer: Positioned above the PET film, the release layer serves as a crucial component during the transfer process. This layer facilitates the separation of the ink and design from the film, ensuring a clean and precise transfer onto the target surface.

Ink Layer: The ink layer contains the actual design, including colors, patterns, and any other visual elements. This layer is specially formulated to respond to heat during the transfer process, allowing the design to be released and adhered to the substrate.

Adhesive Layer: The topmost layer is the adhesive layer, which activates upon exposure to heat. This layer is designed to bond the transferred design securely to the substrate, creating a durable and long-lasting decorative finish.

Heat Transfer Process:

The brilliance of PET heat transfer film lies in its heat-activated transfer process. When subjected to heat, typically through a heat press or similar machinery, the film transforms:

Ink Activation: The heat causes the ink layer to activate and become temporarily liquefied. This transformation enables the ink to separate from the PET film and adhere to the release layer.

Design Transfer: As the release layer is designed to be receptive to the ink under heat, the design seamlessly transfers from the film to the substrate. This transfer occurs with precision, capturing even the finest details of the original design.

Adhesion: Simultaneously, the adhesive layer becomes activated, bonding the transferred design securely to the substrate. The result is a vivid, durable, and high-quality decorative finish.

Applications Across Industries:

The versatility of PET heat transfer film extends across various industries, making it a preferred choice for decorative applications. Some notable applications include:

Textiles and Apparel: PET heat transfer film is extensively used in the textile and apparel industry to create vibrant and detailed designs on garments. This includes T-shirts, sportswear, activewear, and a wide range of fashion items.

Home Decor: The film finds applications in home decor products, such as decorative panels, wall art, and furniture surfaces. Its ability to adhere to different materials makes it a versatile choice for enhancing the aesthetics of living spaces.

Automotive Interiors: PET heat transfer film is utilized in the automotive industry to add decorative elements to interior components, including dashboards, trims, and various surfaces within the vehicle.

Electronics and Appliances: The film's compatibility with different substrates makes it suitable for decorating electronic devices, appliances, and other consumer goods.

Promotional Products: From custom promotional items to branded merchandise, PET heat transfer film offers a cost-effective and visually appealing solution for creating personalized products.

English

English

русский

русский

Español

Español

عربى

عربى

Türk

Türk