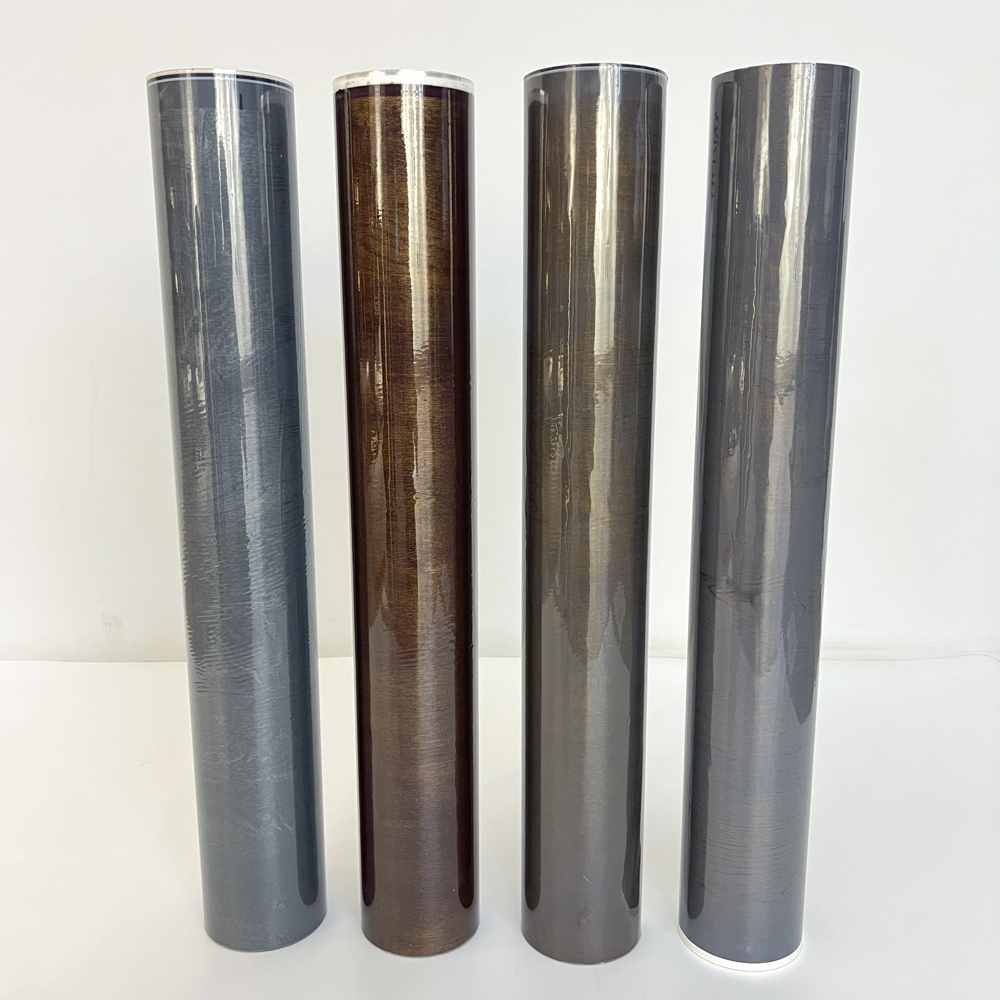

Wood plastic composite (WPC) panels have become a popular choice for a wide range of applications, including decking, wall cladding, and furniture, due to their durability, eco-friendliness, and aesthetic appeal. One of the significant advancements in WPC panel manufacturing is the introduction of Heat Transfer Film for WPC Panel, which allows manufacturers to create realistic wood patterns on composite surfaces. This process not only enhances the visual appeal of the panels but also provides an eco-friendly alternative to traditional wood products.

The Role of Textured Patterns in WPC Panels

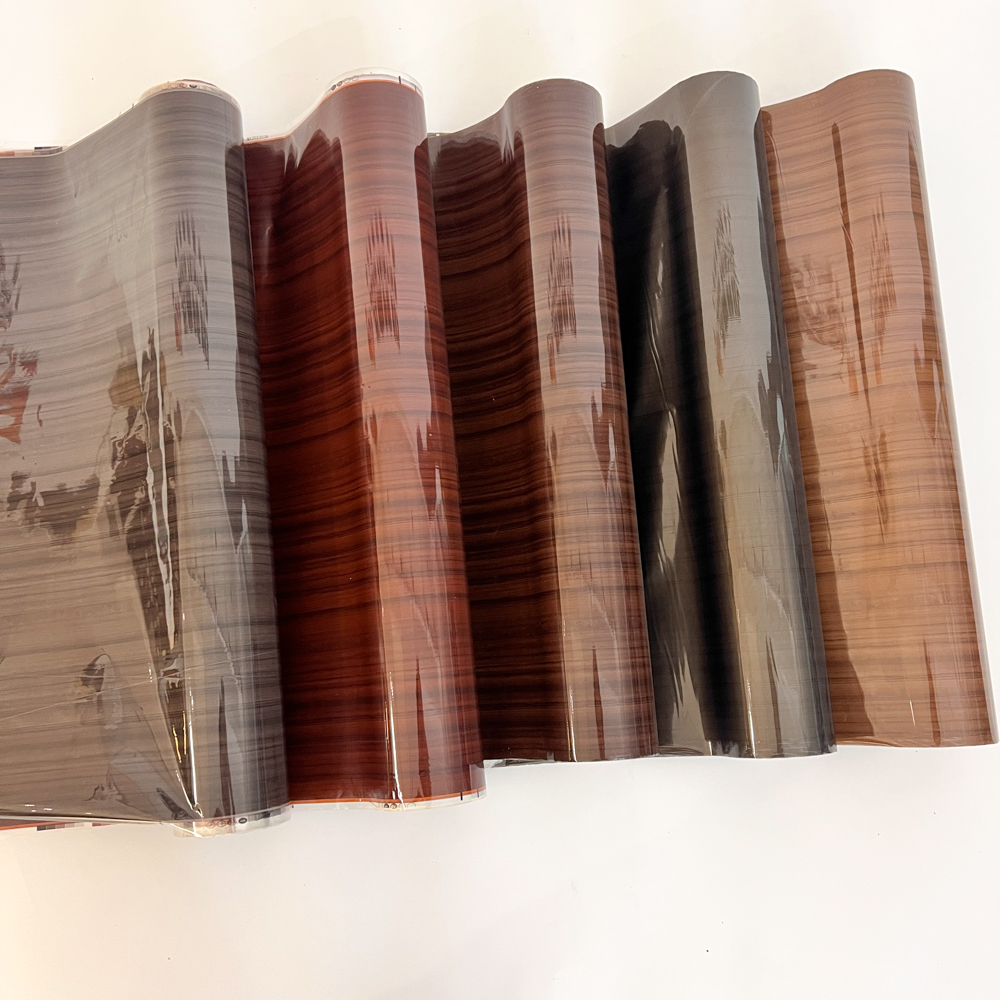

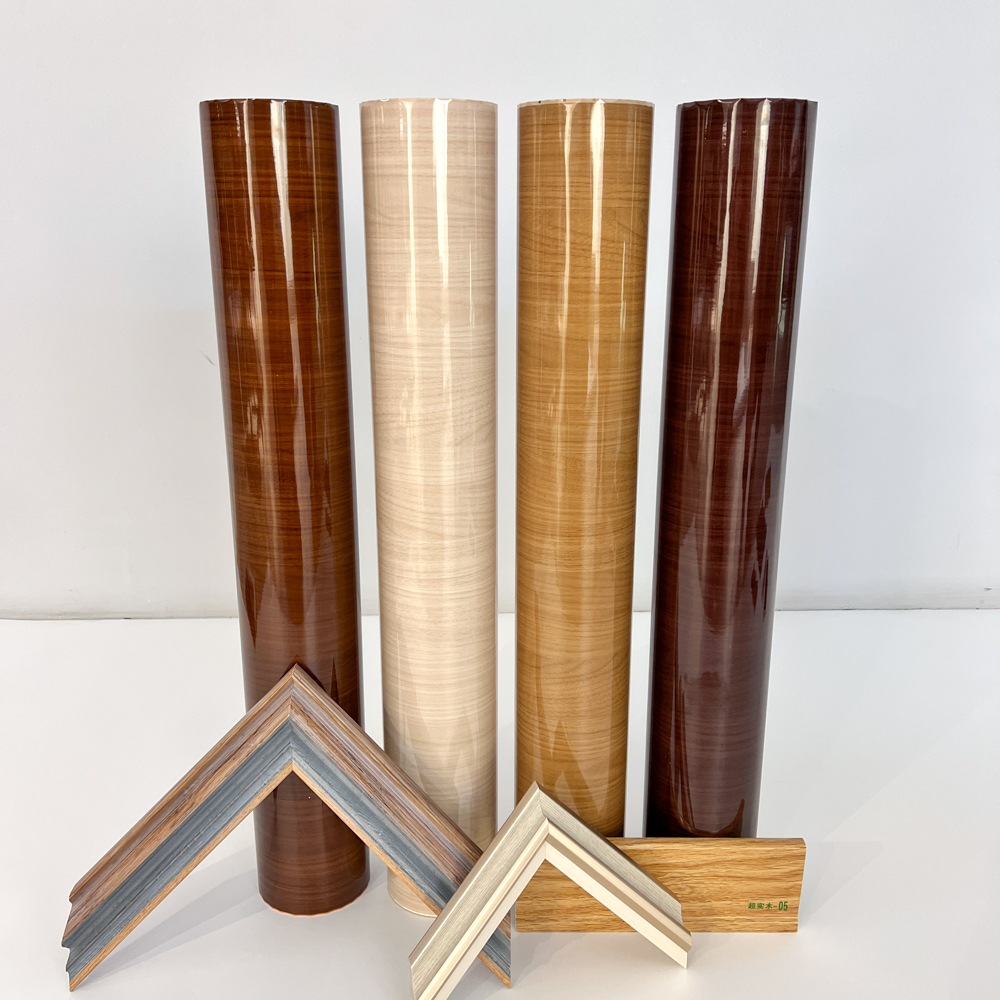

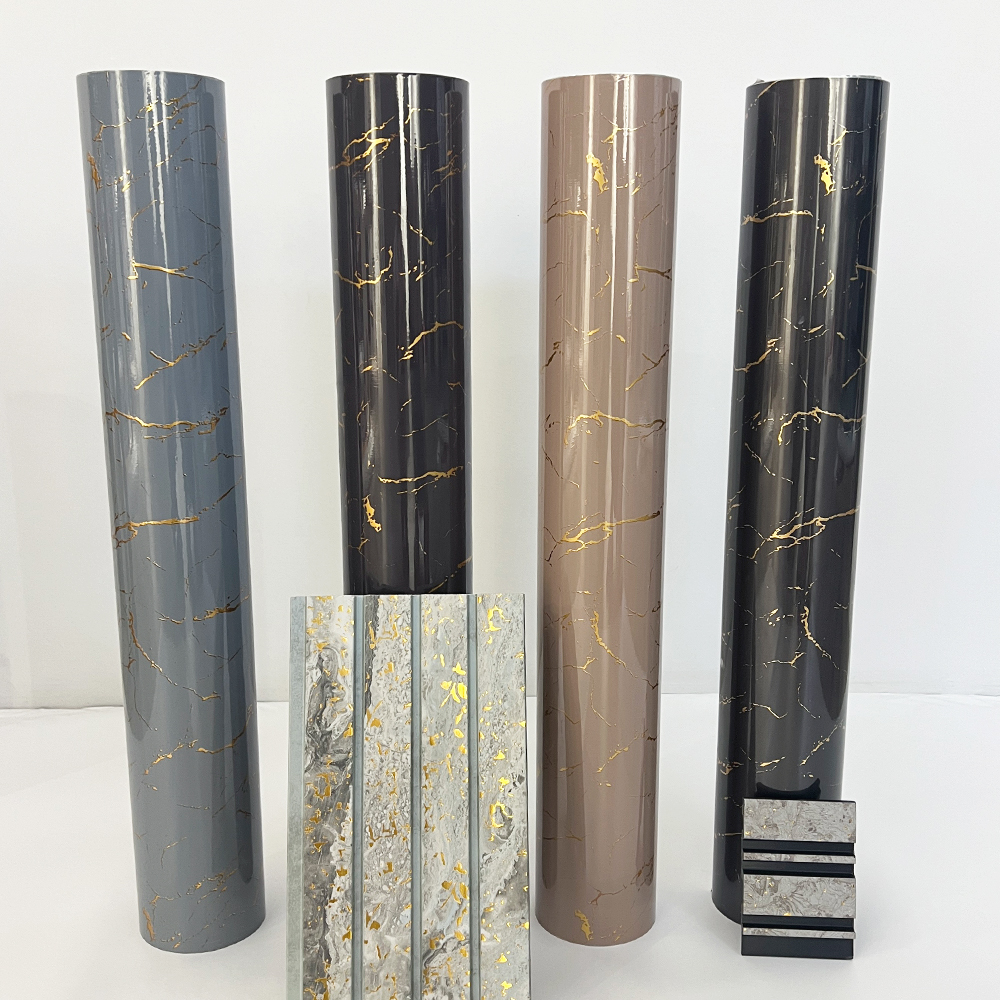

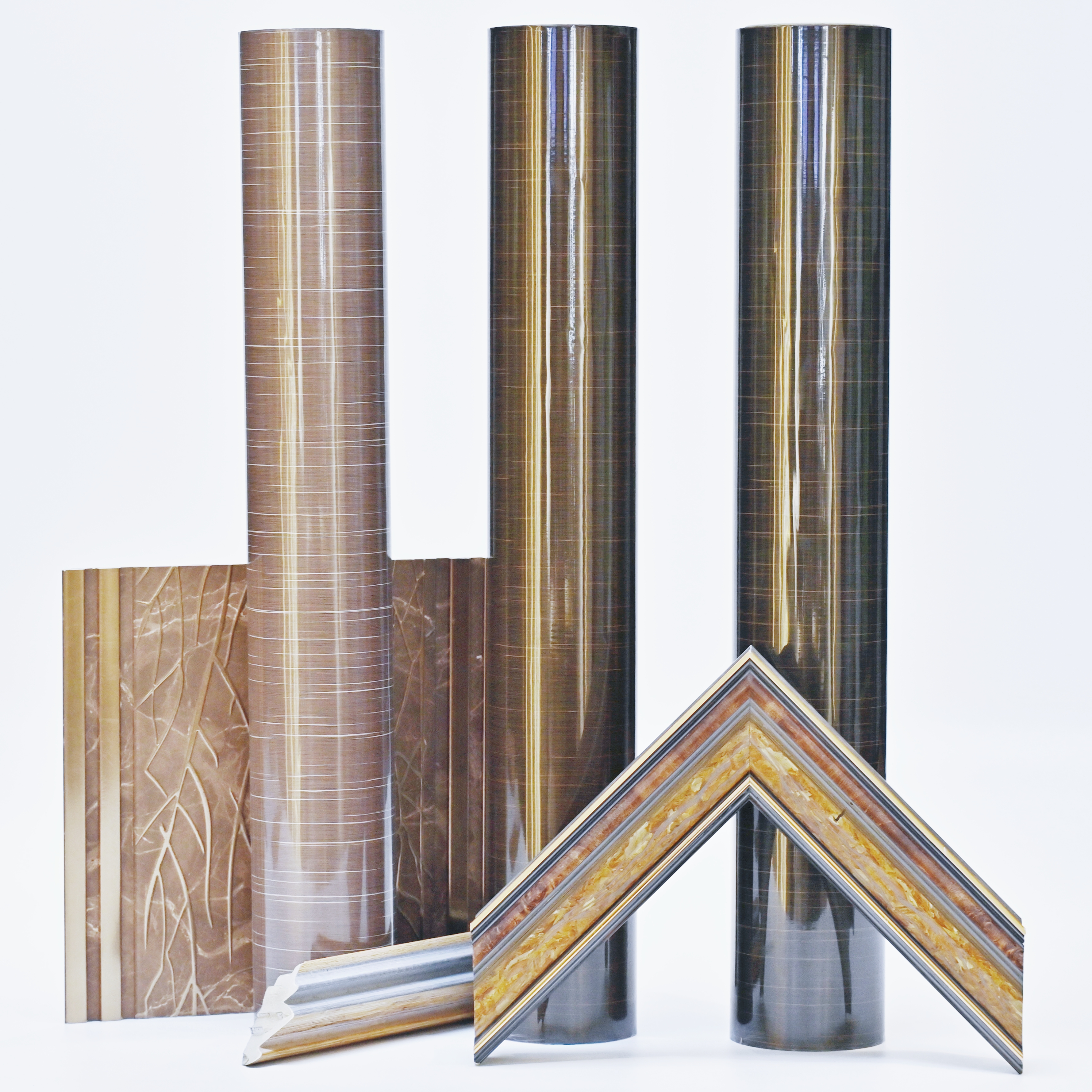

One of the key benefits of using Heat Transfer Film for WPC Panel is the ability to replicate a wide range of textures that are characteristic of natural wood. These textures enhance the aesthetic qualities of WPC panels, making them an attractive alternative to traditional wood products. The texture patterns on these panels can range from smooth to deeply embossed, offering various finishes to suit different design preferences.

The creation of a realistic wood pattern involves the intricate process of mapping natural wood grain onto the WPC panel. To achieve this, the film must closely mimic the variation in grain patterns, including the knots, streaks, and swirls that are unique to wood species. This allows manufacturers to replicate not only the appearance but also the tactile feel of wood, adding authenticity to the composite panel.

The Technology Behind the Pattern Creation

The creation of the texture pattern on Heat Transfer Film for WPC Panel begins with digital imaging technology. High-resolution scanners and computer software are used to capture the texture of actual wood surfaces. The images are then converted into digital patterns that can be reproduced on the heat transfer film.

Digital Imaging and Design:

The process begins by capturing a high-quality photograph or scan of natural wood. These digital images are then processed using specialized software to create a seamless texture pattern. The software allows designers to manipulate the grain, color, and appearance of the wood, adjusting features such as the depth of the grain, the presence of knots, and the overall texture.

Printing the Design onto the Film:

Once the design is finalized, it is printed onto the Heat Transfer Film for WPC Panel using advanced printing technologies such as gravure or flexographic printing. These printing methods ensure that the design is highly detailed, with every grain and knot rendered accurately. The inks used are typically heat-sensitive and designed to bond effectively with the surface of the WPC panel during the transfer process.

Embossing the Texture:

To create a more realistic, three-dimensional appearance, embossing is often used to add depth to the pattern. This involves pressing the heat transfer film onto the WPC panel under high pressure and temperature, which results in the surface of the panel taking on the tactile texture of the wood grain. The embossing process can vary in intensity, from lightly textured finishes to deep, pronounced grain patterns. The depth of embossing directly influences the tactile feel and visual appeal of the final product.

Materials Used in Heat Transfer Film for WPC Panel

The composition of the Heat Transfer Film for WPC Panel plays an important role in achieving high-quality, long-lasting patterns. The film is typically made from a combination of the following materials:

Polyester or PET (Polyethylene Terephthalate): These materials form the base of the transfer film. They are chosen for their durability, heat resistance, and ability to hold intricate designs.

Inks and Dyes: The color and pattern of the film are created using specialized inks that are heat-resistant and capable of bonding with the surface of the WPC panel. These inks are carefully selected to mimic the natural color variations found in wood.

Foil Layer: A thin layer of foil is often added to enhance the adhesion of the design to the panel. This layer helps create the glossy finish often associated with wood surfaces.

Adhesive Coatings: Some films also have a special adhesive layer that facilitates the transfer of the design to the panel under heat and pressure.

中文简体

中文简体

English

English

русский

русский

Español

Español

عربى

عربى

Türk

Türk